Product

Full granulation function and high production efficiency

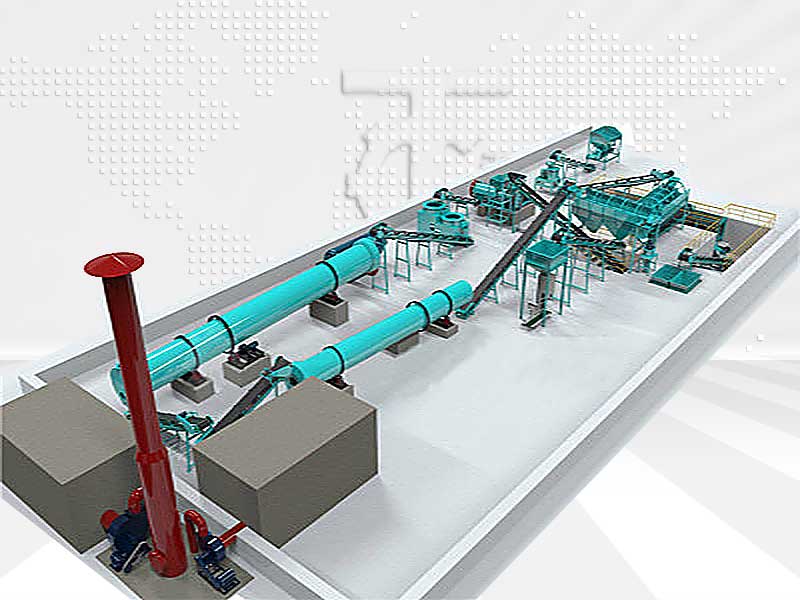

Discount wholesale Cow Dung Drum Granulator - Rotary Drum Granulator-fertilizer pellet manufacturing – Tianci

Discount wholesale Cow Dung Drum Granulator - Rotary Drum Granulator-fertilizer pellet manufacturing – Tianci Detail:

Product Description

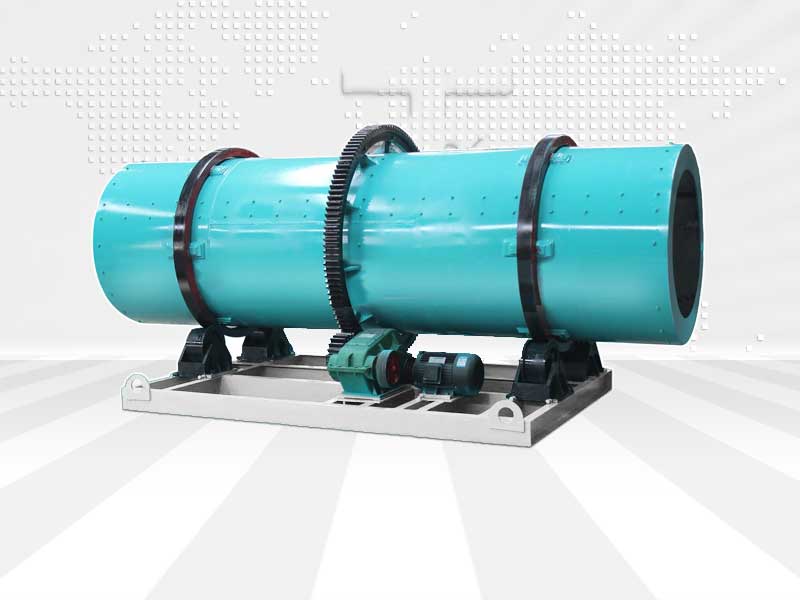

Rotary drum fertilizer granulator is a molding machine that can make material into a particular shape. The rotary drum granulator is one of the key equipment of the organic and compound fertilizer industry.It is suitable for cold or hot granulation and mass production for high and low concentration compound fertilizer. The main operation way is wet type granulation: Through a certain amount of water or steam, the basic fertilizer humidifying in the tank and occurring sufficient chemical reaction. Under a certain liquid conditions, with the rotation of the rotary drum movement, so that produce a squeeze force between the material particles and agglomerate into balls.

Performance Characteristics

1. Technical innovation and structural improvement, the tube adopts special rubber plate lining or acid-resistant stainless steel lining, which realizes automatic scar removal and tumor removal and eliminates the traditional scraper device.

2. High wear resistance, easy maintenance, high ball strength, good appearance quality, corrosion resistance, wear resistance, low energy consumption, long service life, easy operation and maintenance.

3. Reasonable layout, leading technology, small power, no waste discharge, stable operation, convenient maintenance, reasonable process layout, advanced technology, low production cost.

4. High pelletizing rate, high drying efficiency, pelletizing rate up to 70%, with a small amount of return material, return material particle size is small, can be re-granulated;Through steam heating, improve the material temperature

Working Principle

The main working principle is wet type granulation: Through a certain amount of water or steam, the basic fertilizer humidifying in the tank and occurring sufficient chemical reaction. Under a certain liquid conditions, with the rotation of the rotary drum movement, so that produce a squeeze force between the material particles and agglomerate into balls.

Main Technical Parameters

|

Model |

Barrel |

Power |

Prod Capacity |

Overall dimensions L× W ×H |

weight |

|||

|

Inclination |

Internal diameter |

length |

Rotation speed |

|||||

|

0 |

m |

m |

r/min |

kw |

t/h |

m |

t |

|

|

ZG1.2×4 |

2-2.5 |

1.2 |

4 |

17 |

5.5 |

1-3 |

4.6×2.2×2.0 |

2.7 |

|

ZG1.4×5 |

2-2.5 |

1.4 |

5 |

14 |

7.5 |

3-5 |

4.8×2.8×2.3 |

8.5 |

|

ZG1.6×6 |

2-2.5 |

1.6 |

6 |

11.5 |

11 |

5-8 |

7.0×3.2×3.1 |

12.0 |

|

ZG1.8×7 |

2-2.5 |

1.8 |

7 |

11.5 |

15 |

8-10 |

8.3×3.5×3.3 |

18.5 |

|

ZG2.0×8 |

2-2.5 |

2.0 |

8 |

11 |

18.5 |

10-15 |

9.1×3.6×3.5 |

22.0 |

|

ZG2.2×8 |

2-2.5 |

2.2 |

8 |

10.5 |

22 |

15-20 |

9.5×4.4×3.9 |

28.0 |

Product detail pictures:

Related Product Guide:

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of Discount wholesale Cow Dung Drum Granulator - Rotary Drum Granulator-fertilizer pellet manufacturing – Tianci , The product will supply to all over the world, such as: Oman, Indonesia, Brisbane, As an experienced factory we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of the company is to live a satisfactory memory to all the customers, and establish a long term win-win business relationship. For more information, please contact us. And It is our great pleasure if you like to have a personally meeting in our office.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!

Request a Quote

Select model and place orders

Select the model and submit the purchase intention

Get the base price

Manufacturers take the initiative to contact and inform the lo

Plant inspection

Expert training guide, regular return visit

Sign the contract

Select the model and submit the purchase intention

Get the minimum offer free of charge , please fill in the following information to tell us ( confidential information , not open to the public )

If you are interest in our products or need to know more, please click the consultation button on the right

Get quotation

Get quotation +8613203835178

+8613203835178