Product

Full granulation function and high production efficiency

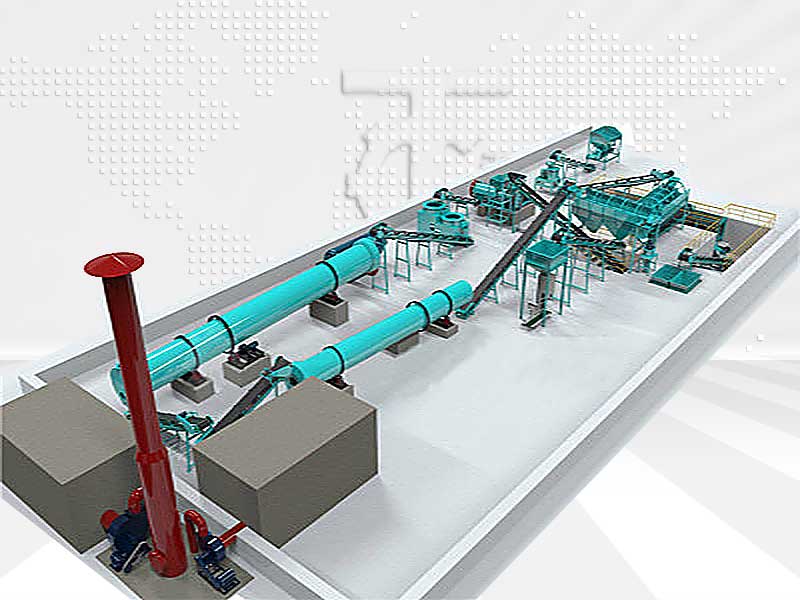

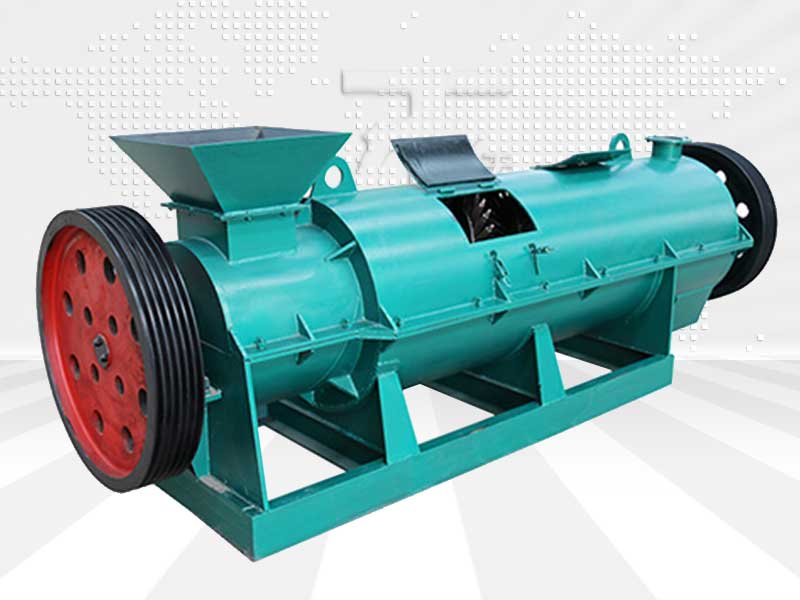

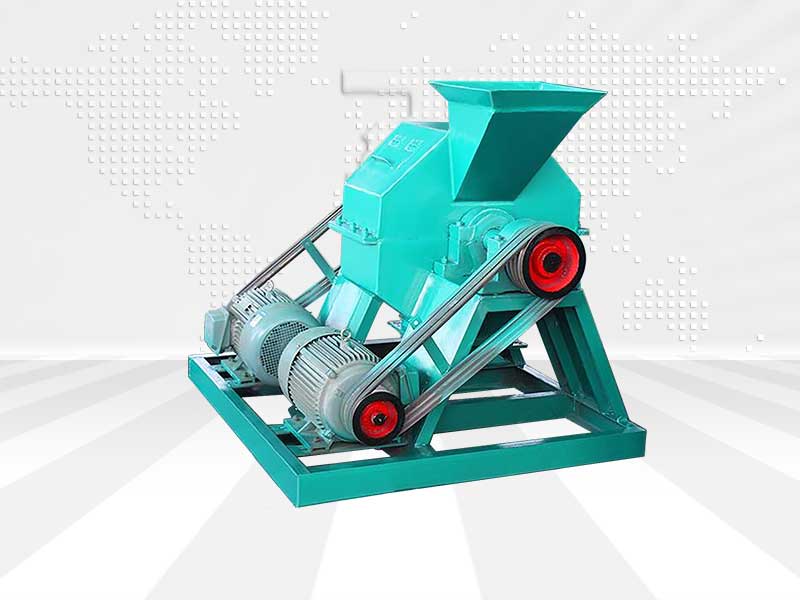

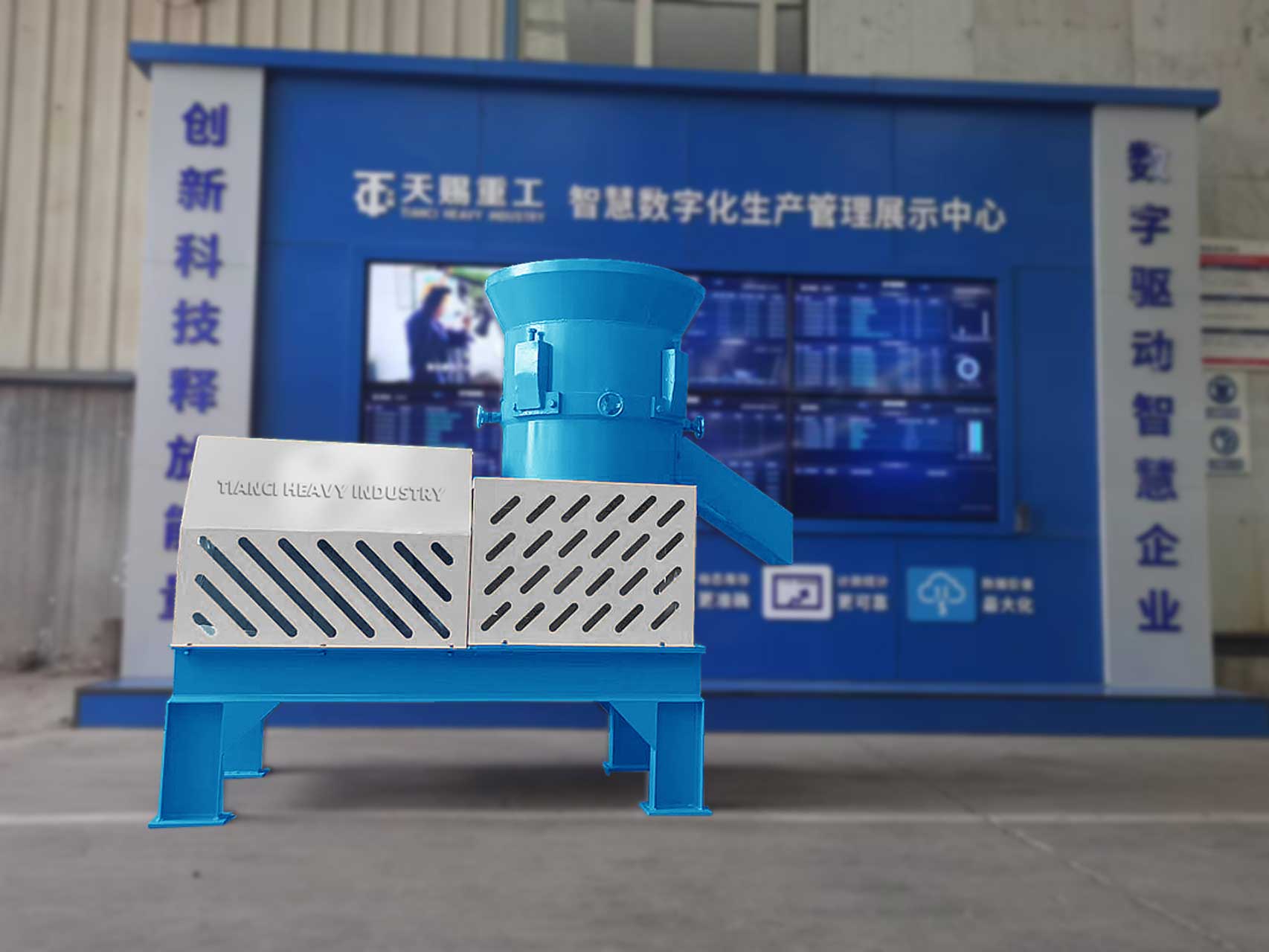

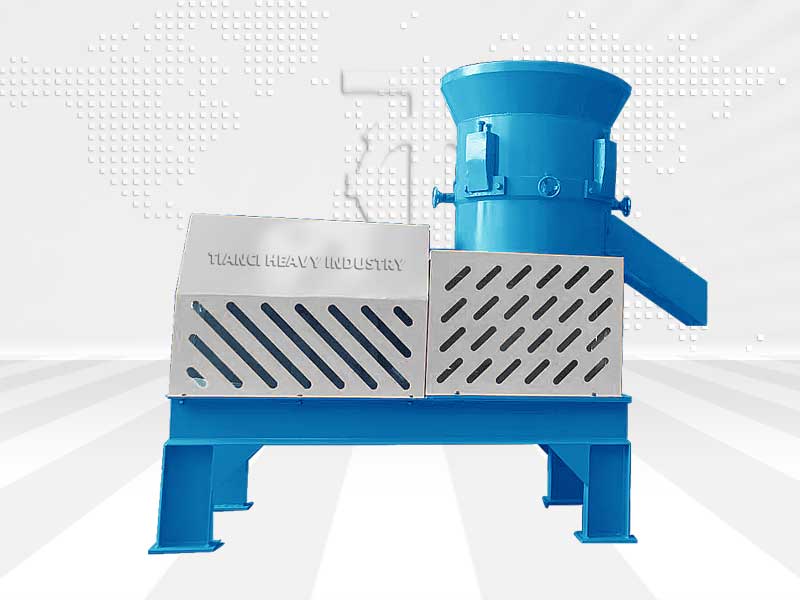

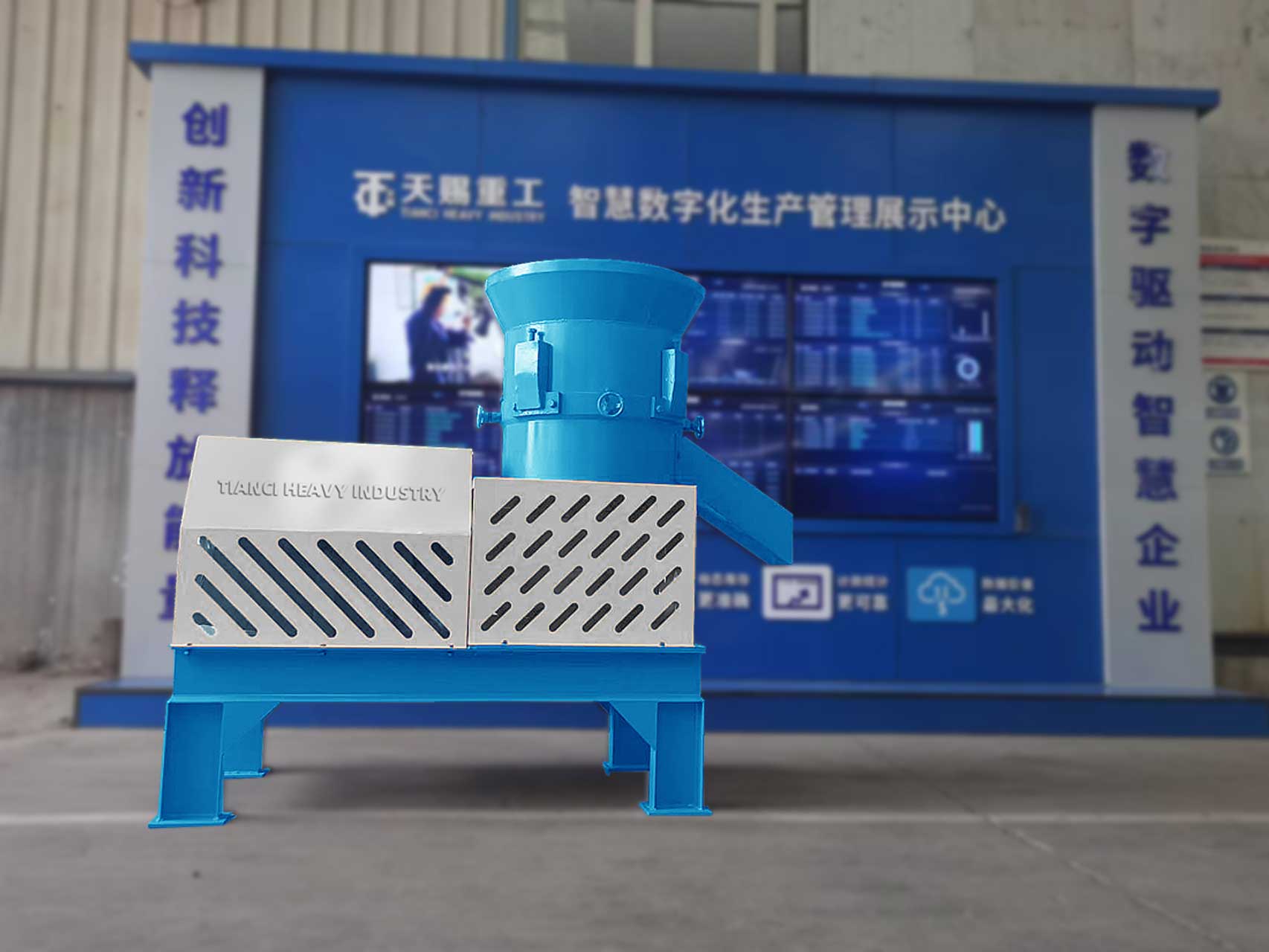

Factory made hot-sale Compound Fertilizer Granulation Machinery - Flat mold granulator – Cylindrical granulator mold – Tianci

Factory made hot-sale Compound Fertilizer Granulation Machinery - Flat mold granulator – Cylindrical granulator mold – Tianci Detail:

Applications and Features

The production from this machine is spherical particles.

The organic content can be as high as 100%, to achieve pure organic granulation.

The granulation does not need add binder, use of organic particles can grow up each other features in a certain force.

The granule is stable, can be screened after granulation, reduce the drying energy consumption.

The raw materials can be with 20-40% moisture. The raw material don’t need drying after fermentation.

Multifunctional organic fertilizer granulation machine is the latest technology granulator machine. It is designed by the Agricultural Machinery Research Institute with many years productions experience on the fertilizer processing equipment. It has won state utility model patents. It is used for granulation of various organic substances after fermentation, breaking the conventional organic granulation process, without drying, crushing and granulating the raw materials before pelletizing, and processing the spherical granules with direct ingredients, thus saving a large amount of energy.

Main Technical Parameters

|

Model |

KP-400 |

KP-600 |

KP-800 |

|

Output |

1.8-2.5 |

2.5-3.5 |

4-5 |

|

Granulation rate |

>95 |

>95 |

>95 |

|

Particle temperature |

<30 |

<30 |

<30 |

|

Particle diameter |

3-30 |

3-30 |

3-30 |

|

Power |

30 |

55 |

75 |

|

Machine weight |

1200 |

1800 |

2500 |

Product detail pictures:

Related Product Guide:

The consumer fulfillment is our primary goal. We uphold a consistent level of professionalism, top quality, credibility and service for Factory made hot-sale Compound Fertilizer Granulation Machinery - Flat mold granulator – Cylindrical granulator mold – Tianci , The product will supply to all over the world, such as: Detroit, New Zealand, Comoros, All styles appear on our website are for customizing. We meet up to personal requirements with all products of your very own styles. Our concept is to help presenting the confidence of each buyers with the offering of our most sincere service, and the right product.

It's really lucky to find such a professional and responsible manufacturer, the product quality is good and delivery is timely, very nice.

Request a Quote

Select model and place orders

Select the model and submit the purchase intention

Get the base price

Manufacturers take the initiative to contact and inform the lo

Plant inspection

Expert training guide, regular return visit

Sign the contract

Select the model and submit the purchase intention

Get the minimum offer free of charge , please fill in the following information to tell us ( confidential information , not open to the public )

If you are interest in our products or need to know more, please click the consultation button on the right

Get quotation

Get quotation +8613203835178

+8613203835178