Product

Full granulation function and high production efficiency

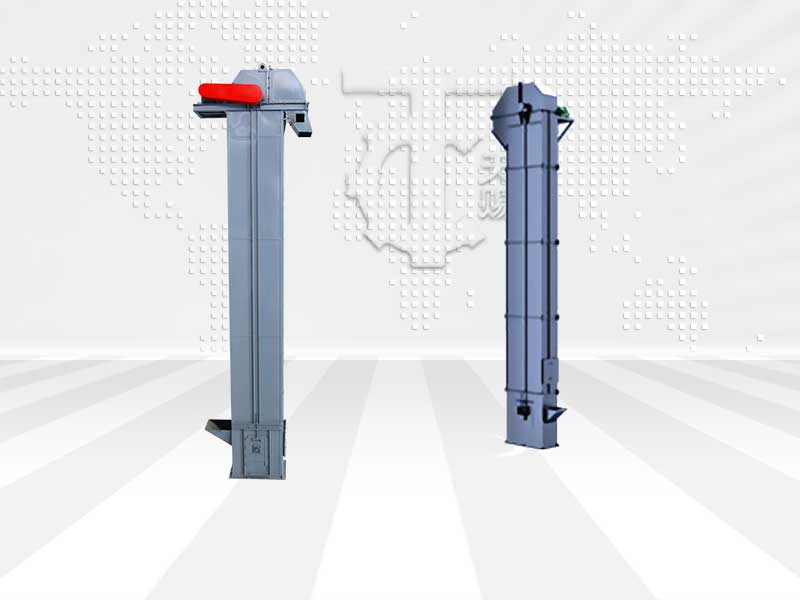

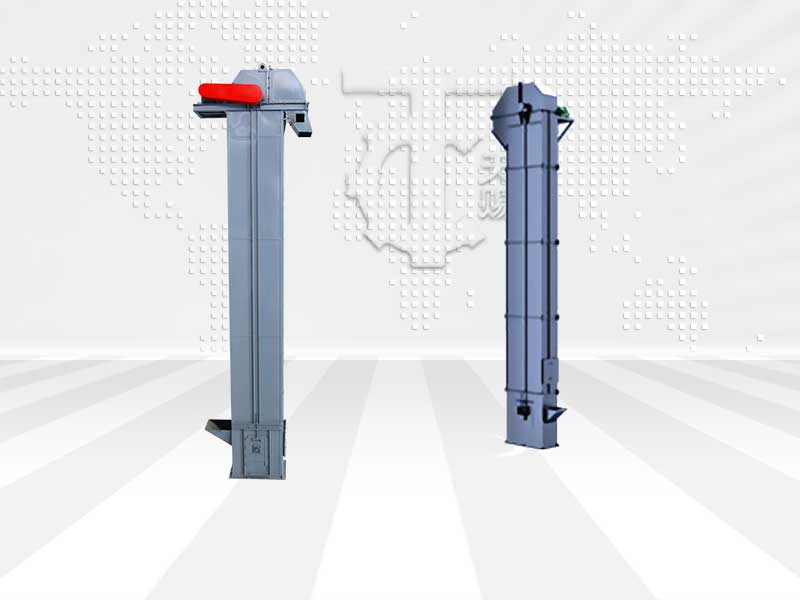

High Quality Organic Manure Production Plant - Bucket Elevator-Lifting height 1-30m – Tianci

High Quality Organic Manure Production Plant - Bucket Elevator-Lifting height 1-30m – Tianci Detail:

Product Description

1. The driving power is small, and the inflow feeding, inductive discharging, and large-capacity hopper are densely arranged. There is almost no returning and digging phenomenon when the material is lifted, so the ineffective power is small.

2. The lifting range is wide. This type of hoist has less requirements on the types and characteristics of materials. It can not only lift general powdery and small granular materials, but also improve materials with greater abrasiveness. It has good sealing performance and less environmental pollution.

3. Good operation reliability, advanced design principles and processing methods ensure the reliability of the whole machine operation, and the trouble-free time exceeds 20,000 hours. High lifting height. The hoist runs smoothly, so a higher lifting height can be achieved.

4. The service life is long, the feeding of the elevator adopts the inflow type, and there is no need to use the bucket to excavate the material, and there is little extrusion and collision between the materials. This machine is designed to ensure that the material is less scattered during feeding and unloading, which reduces mechanical wear and tear.

Main Technical Parameters

|

Model |

Th315 |

Th400 |

Th500 |

Th630 |

|||||||||

|

Hopper form |

ZH |

SH |

ZH |

SH |

ZH |

SH |

ZH |

SH |

|||||

|

Transport volume |

35 |

59 |

58 |

94 |

73 |

118 |

114 |

185 |

|||||

|

Bucket capacity |

3.75 |

6 |

5.9 |

9.5 |

9.3 |

15 |

14.6 |

23.6 |

|||||

|

Bucket distance |

512 |

688 |

|||||||||||

|

Pitch diameter× |

Φ18×64 |

Φ12.1×86 |

|||||||||||

|

Single chain strength |

320 |

480 |

|||||||||||

|

Weight per unit length |

25.64 |

26.58 |

31.0 |

31.9 |

41.5 |

44.2 |

49.0 |

52.3 |

|||||

|

Drive sprocket speed |

42.5 |

37.6 |

35.8 |

31.8 |

|||||||||

|

Conveying max sizes |

35 |

40 |

50 |

60 |

|||||||||

|

Hopper running speed |

1.4 |

1.5 |

|||||||||||

Product detail pictures:

Related Product Guide:

We not only will try our greatest to offer superb companies to just about every buyer, but also are ready to receive any suggestion offered by our shoppers for High Quality Organic Manure Production Plant - Bucket Elevator-Lifting height 1-30m – Tianci , The product will supply to all over the world, such as: Ghana, Macedonia, Italy, Due to our good goods and services, we've received good reputation and credibility from local and international customers. If you will need more information and are interested in any of our solutions, be sure to feel free to contact us. We look forward to becoming your supplier in the near future.

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.

Request a Quote

Select model and place orders

Select the model and submit the purchase intention

Get the base price

Manufacturers take the initiative to contact and inform the lo

Plant inspection

Expert training guide, regular return visit

Sign the contract

Select the model and submit the purchase intention

Get the minimum offer free of charge , please fill in the following information to tell us ( confidential information , not open to the public )

If you are interest in our products or need to know more, please click the consultation button on the right

Get quotation

Get quotation +8613203835178

+8613203835178