Product

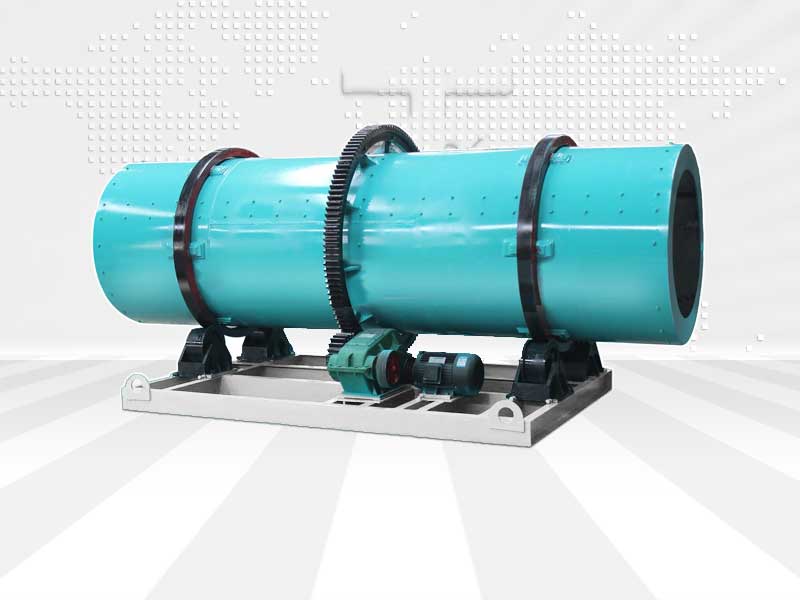

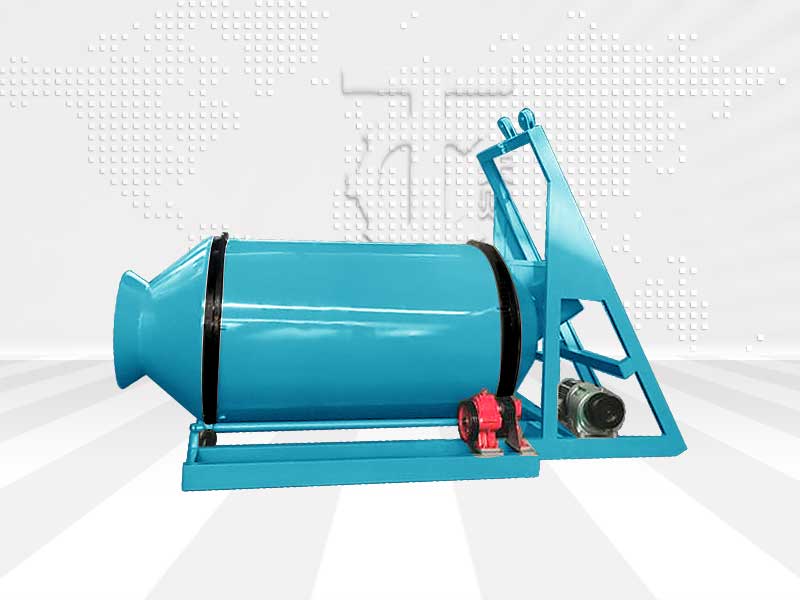

Full granulation function and high production efficiency

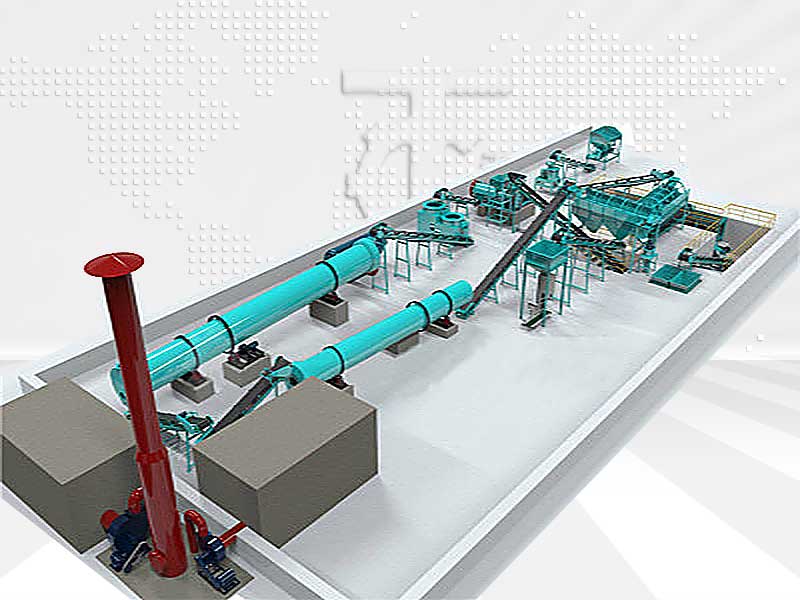

High Quality Organic Manure Production Plant - Dynamic Automatic Batching System – Tianci

High Quality Organic Manure Production Plant - Dynamic Automatic Batching System – Tianci Detail:

Product Description

The dynamic batching machine is suitable for the site of continuous batching,such as fertilizer batching and coking batching.These sites have higher requirements on the continuity of the batching,which generally do not allow the intermediate batching to stop,and the requirements for the proportioning of various materials are strict.The dynamic batching system is usually measured by electronic belt scale or nuclear scale,and the host has PID regulation and alarm function,which can realize the automatic control of a warehouse.

Performance Characteristics

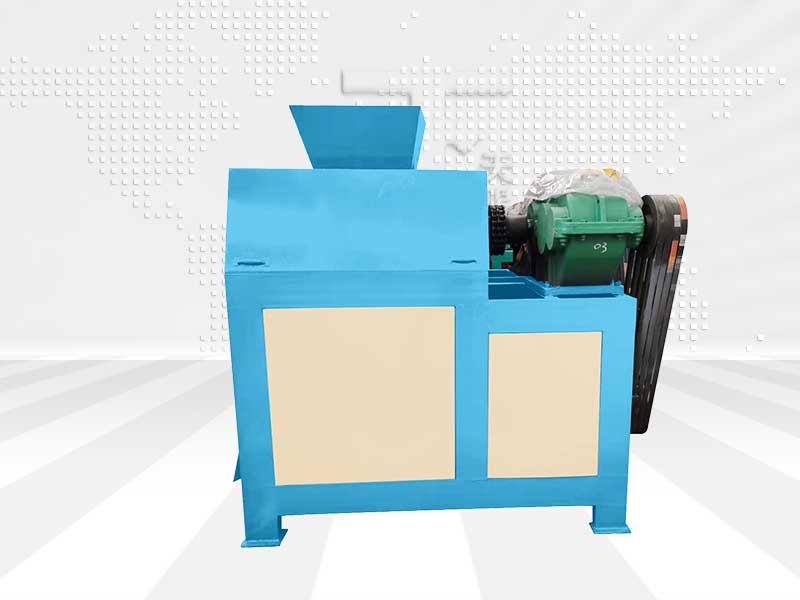

It is suitable for dynamic batching machines such as mixing stations, chemical plants, formula fertilizer processing plants, etc. It has the characteristics of small error, high output and simple operation.

Working Principle

The tape/screw feeder inspects the material passing through the weighing and weighing rack to determine the material quality on the tape; the digital speed sensor at the tail continuously measures the running speed of the feeder; the pulse output of the speed sensor is proportional to the speed of the feeder; the speed signal and the weight signal are one. Take-off and feed into the feeder controller, which is processed by the German microprocessor to generate and display the cumulative/instantaneous flow. The flow rate is compared with the set flow rate, and the frequency converter is controlled by the output signal of the control instrument so as to realize .

Main Technical Parameters

|

Model |

TCDP-3 |

TCDP-4 |

TCDP-5 |

|

Power |

1.1KW*3 |

1.1KW*4 |

1.1KW*5 |

|

Silo size |

1200*1200 |

1200*1200 |

1200*1200 |

|

Precision |

0.5% |

0.5% |

0.5% |

|

Electric control system |

PLC |

PLC |

PLC |

Product detail pictures:

Related Product Guide:

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" as well as the theory of "quality the basic, believe in the 1st and management the advanced" for High Quality Organic Manure Production Plant - Dynamic Automatic Batching System – Tianci , The product will supply to all over the world, such as: Lyon, San Francisco, Israel, Our business activities and processes are engineered to make sure our customers have access to widest range of products with the shortest supply time lines. This achievement is made possible by our highly skilled and experienced team. We look for people who want to grow with us around the globe and stand out from the crowd. We now have people who embrace tomorrow, have vision, love stretching their minds and going far beyond what they thought was achievable.

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.

Request a Quote

Select model and place orders

Select the model and submit the purchase intention

Get the base price

Manufacturers take the initiative to contact and inform the lo

Plant inspection

Expert training guide, regular return visit

Sign the contract

Select the model and submit the purchase intention

Get the minimum offer free of charge , please fill in the following information to tell us ( confidential information , not open to the public )

If you are interest in our products or need to know more, please click the consultation button on the right

Get quotation

Get quotation +8613203835178

+8613203835178