Product

Full granulation function and high production efficiency

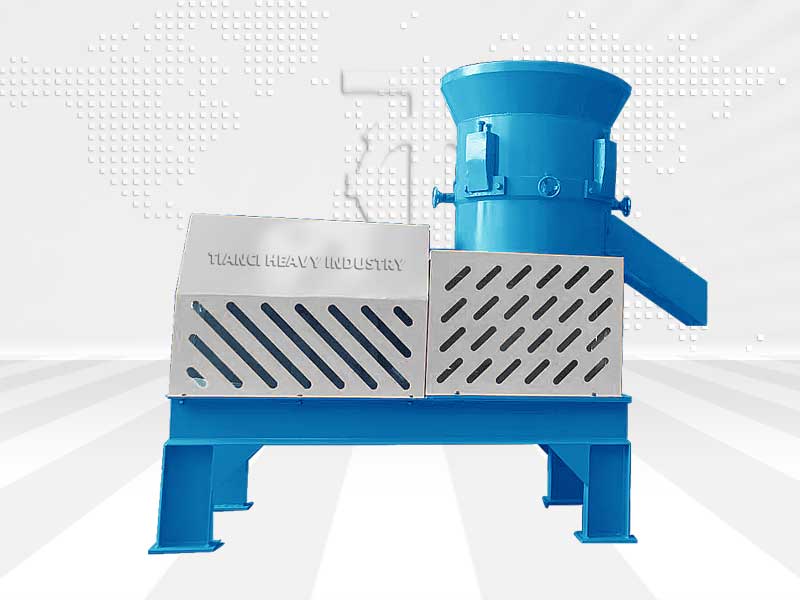

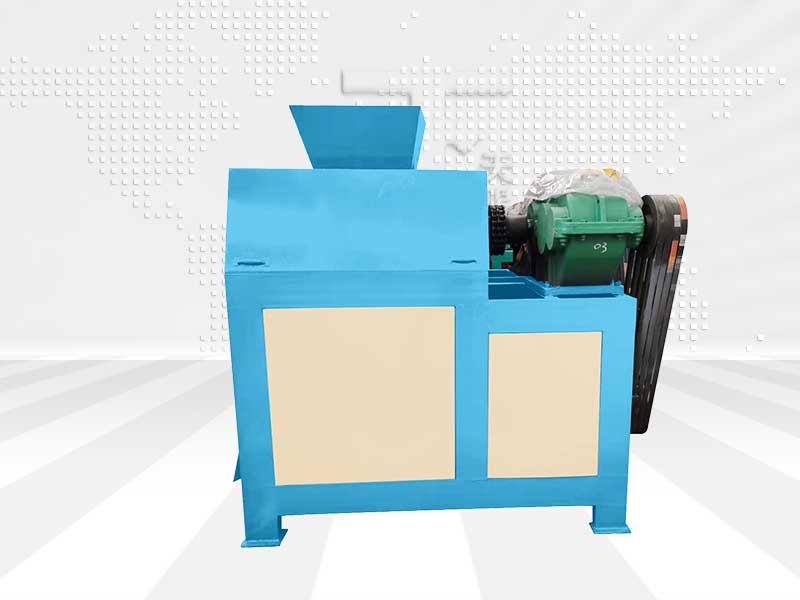

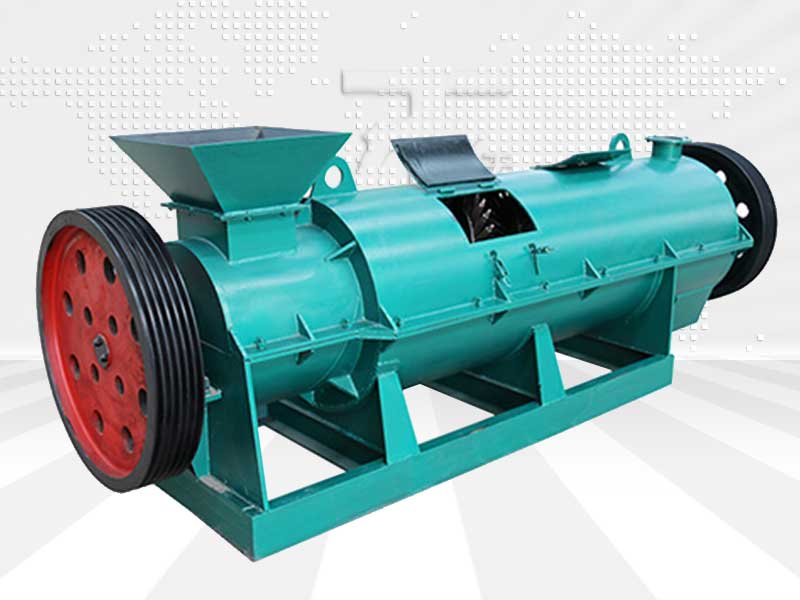

Hot New Products Compound Fertilizer Dry Powder Extrusion Granulator – Vibrating dryer-Heat preservation dryer – Tianci

Hot New Products Compound Fertilizer Dry Powder Extrusion Granulator – Vibrating dryer-Heat preservation dryer – Tianci Detail:

Product Description

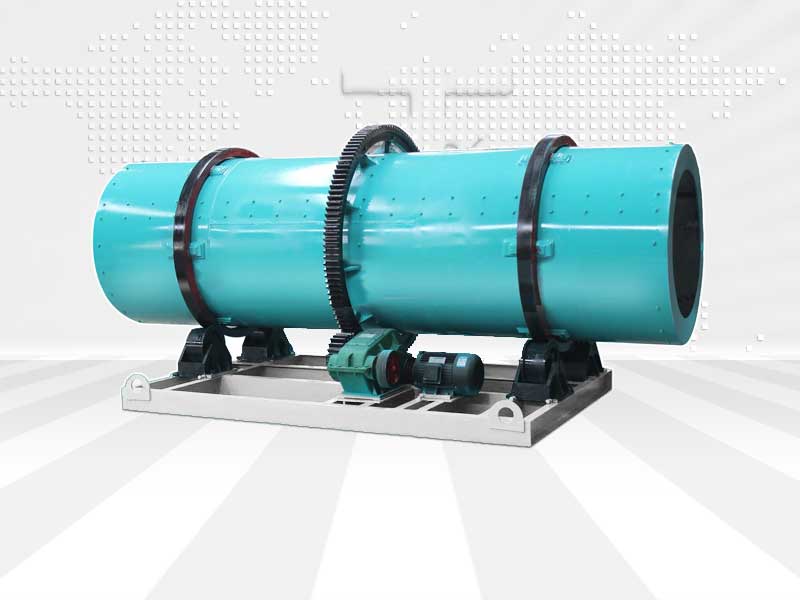

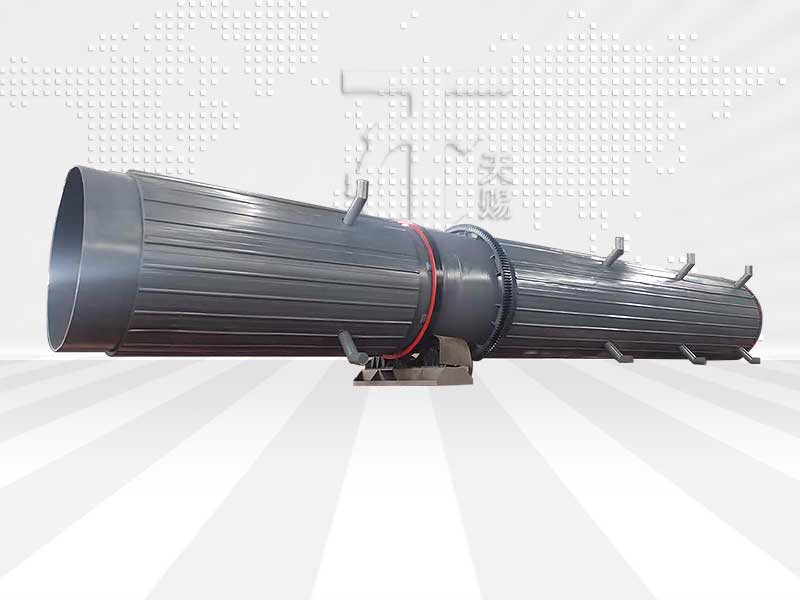

Rotary dryer is one of the traditional drying equipments. It has reliable operation, large operation flexibility, strong adaptability and large processing capacity. It is widely used in metallurgy, building materials, chemical industry, coal washing, fertilizer, ore, sand, clay, kaolin, sugar, etc. Field, diameter: Φ1000mm-Φ4000mm, the length is determined according to the drying requirements.In the center of the tumble dryer, the breaking mechanism can be avoided, and the wet material entering the drying cylinder is repeatedly picked up and thrown by the copy board on the wall of the rotating cylinder, and is broken into fine particles by the dispersing device during the falling process. The specific area is greatly increased, and it is in full contact with the hot air and dried.

Performance Characteristics

The material will not adhere to the inner wall

On the main cylinder of the vibration dryer, there are several groups of small cylindrical cylinders in the shape of ’7′. During the rotation of the cylinder with the dryer, the cylinder vibrates and knocks the cylinder, causing the cylinder to vibrate. Therefore, the materials bonded on the inner wall of the drying cylinder can be separated from the inner wall of the cylinder with the vibration of the cylinder, so the purpose of non bonding the dryer cylinder is realized.

High efficiency in heatin

The distribution and angle of the lifting plate of the rotary dryer are reasonable and the performance is reliable, so the heat energy utilization rate is high and the drying is uniform.

Lower energy consumption

The rotary dryer has a large processing capacity, low fuel consumption, and low drying cost.

Reduces wear

The rotary dryer equipment adopts a self-aligning tug structure, and the tug and the rolling ring cooperate well, which greatly reduces wear and power consumption.

The dryer has the characteristics of high temperature resistance and can quickly dry materials with high temperature hot air. The scalability is strong and the design takes into account the production margin.

Working Principle

The rotary dryer is mainly composed of a rotating body, a lifting plate, a transmission device, a supporting device and a sealing ring. The dried wet material is sent to the hopper by a belt conveyor or a bucket elevator, and then fed through the hopper through the feeding pipe into the feed end. The slope of the feeding pipe is greater than the natural inclination of the material so that the material flows smoothly into the dryer. The dryer cylinder is a rotating cylinder that is slightly inclined to the horizontal. The material is added from the higher end, the heat carrier enters from the lower end, and is in countercurrent contact with the material, and the heat carrier and the material are simultaneously flowed into the cylinder. As the rotating material of the cylinder is moved by gravity to the lower end. During the forward movement of the wet material in the cylinder body, the heat supply of the heat carrier is directly or indirectly obtained, so that the wet material is dried, and then sent out at the discharge end through a belt conveyor or a screw conveyor.

Main Technical Parameters

|

Model |

Shell |

Prod capacity |

Inlet temp ofhot air |

Outlet temp ofhot air |

Motor |

Decelevators model |

|||||

|

Inner diam |

length |

inclination |

Rotation speed |

Model |

Power |

Rotation Speed |

|||||

|

mm |

mm |

0 |

r/min |

t/h |

°C |

°C |

|||||

|

ZG12120 |

1200 |

12000 |

2-5 |

4.7 |

2-2.5 |

150-250 |

60-80 |

Y160M-4 |

7.5 |

1460 |

ZQ350 |

|

ZG15120 |

1500 |

12000 |

2-5 |

5.0 |

4-6 |

150-250 |

60-80 |

Y160L-4 |

15 |

1440 |

ZQ400 |

|

ZG15150 |

1500 |

15000 |

2-5 |

5.0 |

5-7 |

150-250 |

60-80 |

Y160L-4 |

15 |

1440 |

ZQ500 |

|

ZG18150 |

1800 |

15000 |

2-5 |

3.9 |

7-10 |

150-250 |

60-80 |

Y200L1-6 |

18.5 |

970 |

ZQ500 |

|

ZG20200 |

2000 |

20000 |

2-5 |

3.9 |

8-14 |

150-250 |

60-80 |

Y200L2-6 |

22 |

970 |

ZQ650 |

|

ZG22220 |

2200 |

22000 |

2-5 |

3.2 |

12-16 |

150-250 |

60-80 |

Y250M-6 |

37 |

980 |

ZQ750 |

|

ZG24240 |

2200 |

24000 |

2-5 |

3.0 |

14-19 |

150-250 |

60-80 |

Y280S-6 |

45 |

970 |

ZQ850 |

Product detail pictures:

Related Product Guide:

We'll make every effort and hard work being outstanding and excellent, and speed up our techniques for standing during the rank of global top-grade and high-tech enterprises for Hot New Products Compound Fertilizer Dry Powder Extrusion Granulator – Vibrating dryer-Heat preservation dryer – Tianci , The product will supply to all over the world, such as: Portugal, Luxemburg, Tunisia, We offer OEM services and replacement parts to meet the varying needs of our customers. We offer competitive price for quality products and we will make certain your shipment is handled quickly by our logistics department. We sincerely hope to have the opportunity to meet with you and see how we can help you further your own business.

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.

Request a Quote

Select model and place orders

Select the model and submit the purchase intention

Get the base price

Manufacturers take the initiative to contact and inform the lo

Plant inspection

Expert training guide, regular return visit

Sign the contract

Select the model and submit the purchase intention

Get the minimum offer free of charge , please fill in the following information to tell us ( confidential information , not open to the public )

If you are interest in our products or need to know more, please click the consultation button on the right

Get quotation

Get quotation +8613203835178

+8613203835178