Product

Full granulation function and high production efficiency

Professional China Fertilizer Mixing Plant - Horizontal Mixer-High water content organic matter grinder – Tianci

Professional China Fertilizer Mixing Plant - Horizontal Mixer-High water content organic matter grinder – Tianci Detail:

Applications and Features

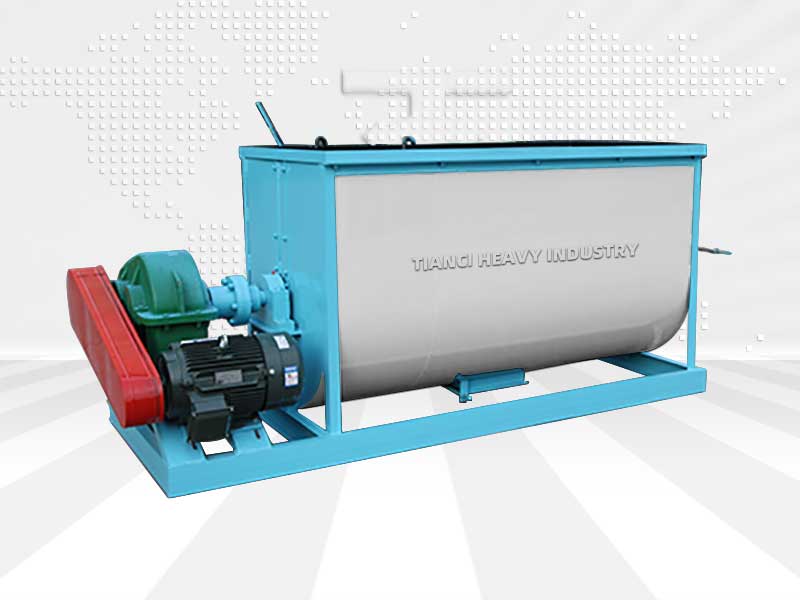

Horizontal mixer machine can mix the material with high uniformity and less residue. It is very suitable for the animal feed, concentrated feed, additive premix mixture. Mixed with high uniformity, less residue, suitable for more than two kinds of fertilizer, additive premix mixture.

The specific features of the horizontal mixer is as bellow

1. The material can be fully mixed, so mixing uniformity is highly improved.

2. The mixer structure is innovative rotor structure , the minimum gap between the rotor and the shell can be adjusted to close to zero, effectively reducing the amount of material residue;

3. The machine with grease to add pipelines, the overall structure is more reasonable, Easy operation and maintenance.

The working principle for horizontal mixer machine:

Horizontal cylinder body with rotating reverse the blade, the pulp into a certain angle of the material along the axial, radial cycle stir, so that the material quickly mixed .

Horizontal mixer performance characteristics, reducer drive shaft rotation speed and the structure of the blade will make the material gravity weakened, with the lack of gravity, the material size of the particles, the proportion of disparity in the mixing process is ignored

The intense mixing movement shortens the time of mixing, faster and more efficient. Even if the material has a specific gravity, the difference in particle size, in the staggered arrangement of the mixing blade fast and violent throwing thrown, but also to achieve a good mixing effect.

Main Technical Parameters

|

Model |

Prod capacity(t/h) |

Power(kw) |

|

600×1200 |

2-3 |

5.5 |

|

700×1500 |

3-5 |

7.5 |

|

900×1500 |

4-8 |

11 |

|

1000×2000 |

8-10 |

15 |

Product detail pictures:

Related Product Guide:

Our firm aims to operating faithfully, serving to all of our consumers , and working in new technology and new machine continually for Professional China Fertilizer Mixing Plant - Horizontal Mixer-High water content organic matter grinder – Tianci , The product will supply to all over the world, such as: Uruguay, Madras, Peru, Our company will continue to serve customers with best quality, competitive price and timely delivery & the best payment term! We sincerely welcome friends from all over the world to visit& cooperate with us and enlarge our business. If you are interested in our products, please do not hesitate to contact us, we will be happy to provide you with further information!

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.

Request a Quote

Select model and place orders

Select the model and submit the purchase intention

Get the base price

Manufacturers take the initiative to contact and inform the lo

Plant inspection

Expert training guide, regular return visit

Sign the contract

Select the model and submit the purchase intention

Get the minimum offer free of charge , please fill in the following information to tell us ( confidential information , not open to the public )

If you are interest in our products or need to know more, please click the consultation button on the right

Get quotation

Get quotation +8613203835178

+8613203835178