Product

Full granulation function and high production efficiency

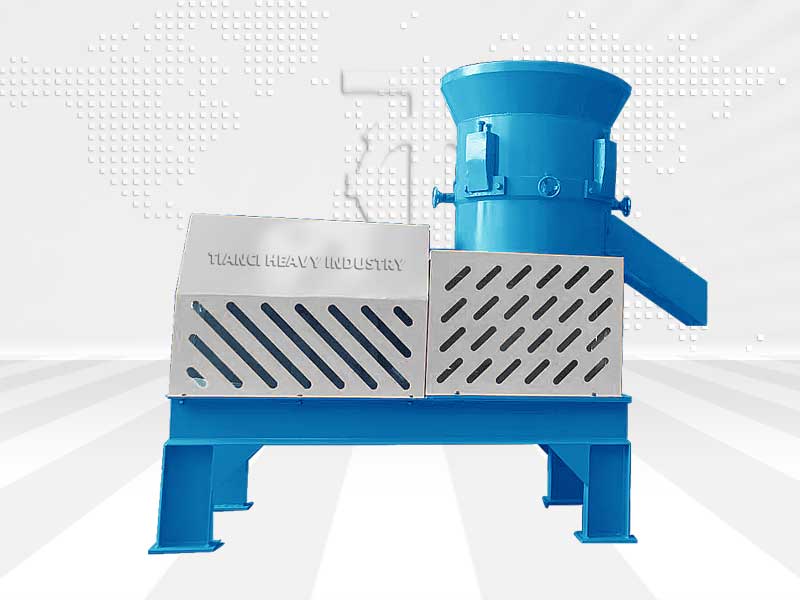

Professional China Fertilizer Mixing Plant - Vertical grinder, disc shape – Tianci

Professional China Fertilizer Mixing Plant - Vertical grinder, disc shape – Tianci Detail:

Applications and Features

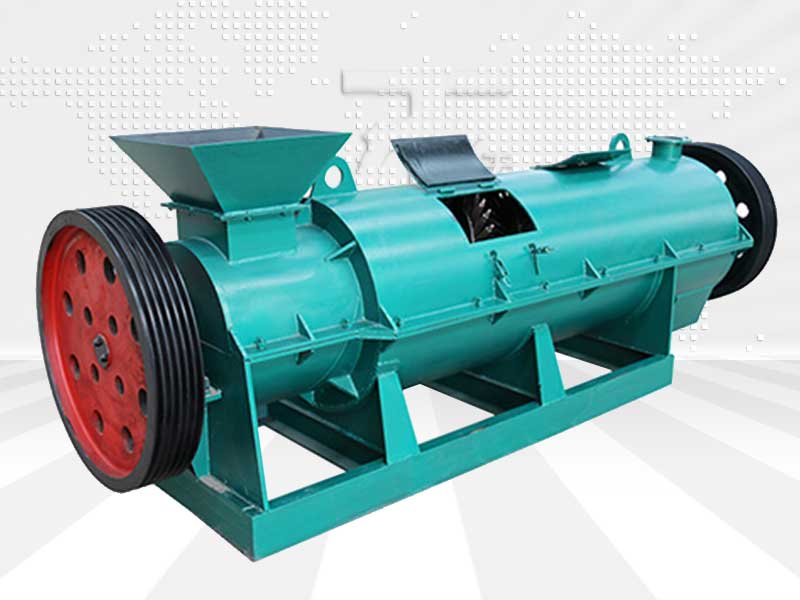

Disc mixer is a kind of machine which is mainly used for mixing raw materials. The machine is made of polypropylene plate lining or stainless steel plate, which is not easy to stick and wear resistance. The cycloidal pinwheel reducer has the advantages of compact structure, convenient operation, uniform mixing and convenient unloading and conveying.

The materials are fully mixed, thereby improving the mixing uniformity, a novel rotor structure, the minimum clearance of the rotor and the shell can be adjusted to close to zero, effectively reduce the residual material, disc uses polypropylene plate lining or stainless steel plate, so it is not easy to stick, abrasion resistance, using cycloid reducer has the advantages of compact structure, convenient operation, uniform mixing and unloading transportation convenience and so on. The overall structure is more reasonable, beautiful appearance, convenient operation and maintenance.

The working principle of the disc mixer: the motor drives the reducer, the reducer drives the spindle, and the spindle drives the stirring material.

Disc mixer structure: all the working body of the machine is installed and fixed on the frame. The frame of the machine is made of carbon steel plate and welded with channel steel. And through the strict product certification and specific process requirements to achieve the purpose of use.

Main Technical Parameters

|

Model |

Mixer |

Rotate Speed (r/min) |

Power (kw) |

Prod Capacity (t/h) |

Overall dimensions (LWH)(mm) |

Quality (Kg) |

|

|

Diameter (mm) |

Wall Height (mm) |

||||||

|

PJ1600 |

1600 |

400 |

12 |

5.5 |

3-5 |

1612×1612×1368 |

1200 |

|

PJ1800 |

1800 |

400 |

10.5 |

7.5 |

4-6 |

1900×1812×1368 |

1400 |

|

PJ2200 |

2200 |

500 |

10.5 |

11 |

6-10 |

2300×2216×1503 |

1668 |

|

PJ2500 |

2500 |

550 |

9 |

15 |

10-16 |

2600×2516×1653 |

2050 |

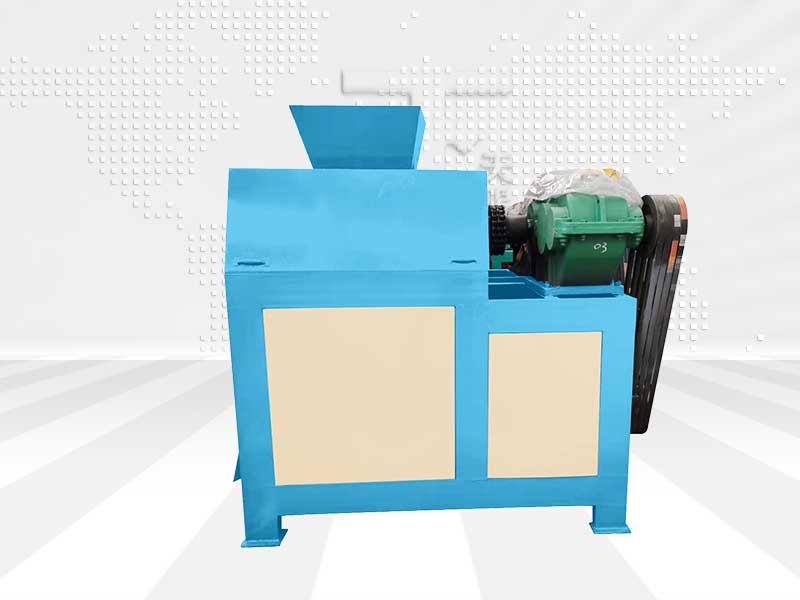

Product detail pictures:

Related Product Guide:

Our business puts emphasis over the administration, the introduction of talented staff, plus the construction of employees building, striving hard to boost the standard and liability consciousness of staff members. Our corporation successfully attained IS9001 Certification and European CE Certification of Professional China Fertilizer Mixing Plant - Vertical grinder, disc shape – Tianci , The product will supply to all over the world, such as: Rotterdam, Bangkok, Provence, Look forward to the future, we will focus more on the brand building and promotion . And in the process of our brand global strategic layout we welcome more and more partners join us, work together with us based on mutual benefit. Let's develop market by fully utilizing our comprehensive advantages and strive for building.

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.

Request a Quote

Select model and place orders

Select the model and submit the purchase intention

Get the base price

Manufacturers take the initiative to contact and inform the lo

Plant inspection

Expert training guide, regular return visit

Sign the contract

Select the model and submit the purchase intention

Get the minimum offer free of charge , please fill in the following information to tell us ( confidential information , not open to the public )

If you are interest in our products or need to know more, please click the consultation button on the right

Get quotation

Get quotation +8613203835178

+8613203835178