Product

Full granulation function and high production efficiency

Renewable Design for Fertilizer Blending Plant - Organic Fertilizer Production Line – Tianci

Renewable Design for Fertilizer Blending Plant - Organic Fertilizer Production Line – Tianci Detail:

Product Description

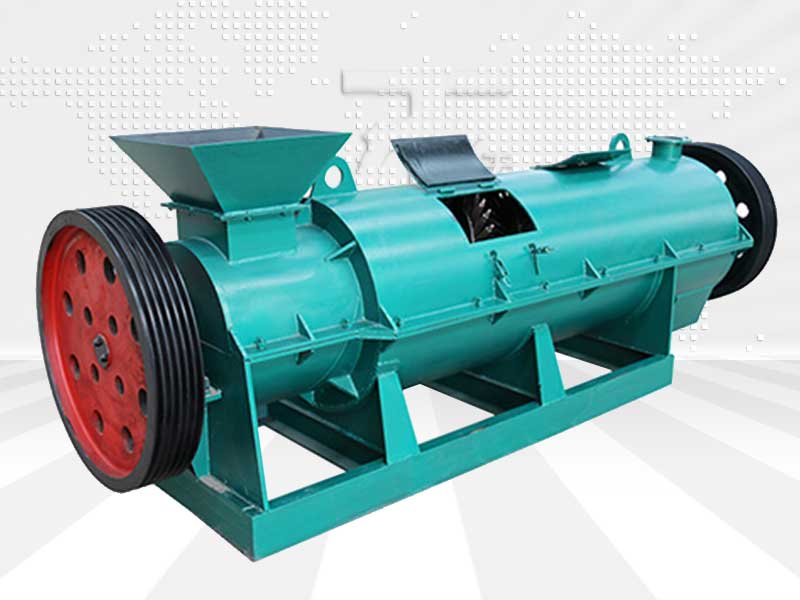

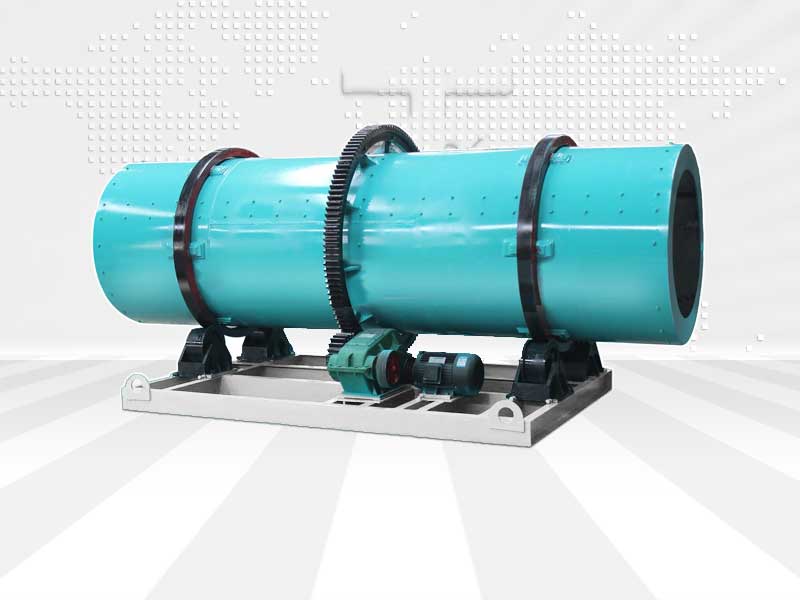

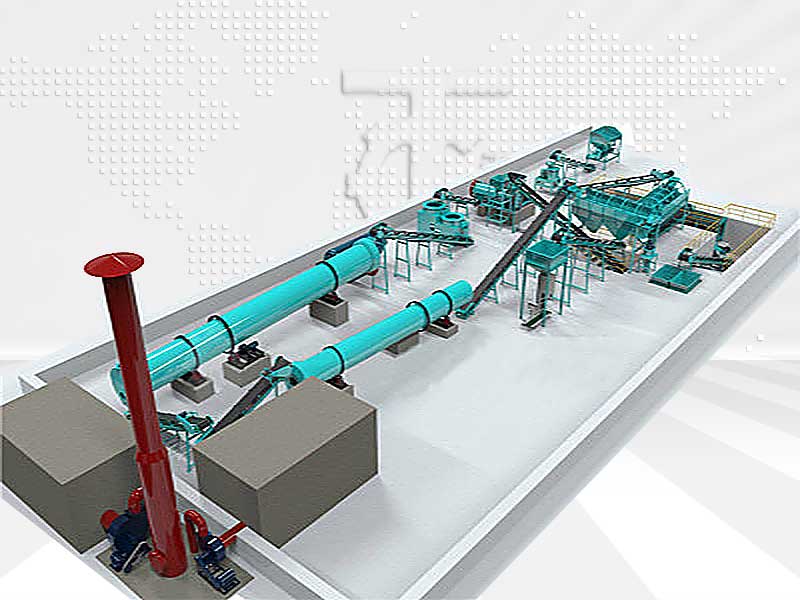

The rapid development of livestock and poultry farming produces a lot of excrement and sewage. The harmful elements of these fouling are too high to be processed by traditional returning way. For this situation, our company has developed the organic fertilizer production line which use high efficient solid-liquid rotten aseptic deodorization technology as the core, and the whole production equipment process includes: high efficient excrement, raw material mixing, granule processing, drying and packing.

Characteristics of Performance

The products of organic fertilizer production line are made of fresh chicken and pig manure, without any chemical composition. The digestive ability chickens and pigs is poor, so they can only consume 25% of nutrients, then another 75% in feed will be excreted with faeces, so that the dry product will contain nitrogen, phosphorus, potassium, organic matter, amino acid, protein and other ingredients. In the urine and manure of livestock, a year of excrement urine of a pig, combined with the cushion material can be retted 2000 a 2500kg high quality organic fertilizer. It contains 11% of organic matter, 12% of organic matter, 0.45% of nitrogen, 0.19% of phosphorous oxide, 0.6% of potassium oxide, and is enough fertilizer for the fertilizer of whole year. These organic fertilizer is rich in nitrogen, phosphorus, potassium and other nutrients, with more than 6% content and more than 35% organic matter content, all of these is above national standard.

Working Principle

An organic fertilizer production line can not only meet the needs of local fertilizer, but also meet the needs of the surrounding market. Biological organic fertilizer is widely used in fields such as farmland, fruit trees, flowers, landscaping, high grade lawn, soil improvement and so on, which have a good effect. Our country subsidizes the agriculture, and it is very supportive of the industry, so investing in this industries is a good choice.

Product detail pictures:

Related Product Guide:

We can normally fulfill our respected consumers with our great excellent, great value and good provider due to we're much more specialist and extra hard-working and do it in cost-effective way for Renewable Design for Fertilizer Blending Plant - Organic Fertilizer Production Line – Tianci , The product will supply to all over the world, such as: Czech republic, Angola, South Korea, As a well educated, innovative and energetic staff,we are responsible for all elements of the research, design, manufacturing, sales and distribution. With studying and developing new techniques,we are not only following but also leading the fashion industry. We listen attentively to the feedback from our customers and provide instant communication. You will instantly feel our expertise and attentive service.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!

Request a Quote

Select model and place orders

Select the model and submit the purchase intention

Get the base price

Manufacturers take the initiative to contact and inform the lo

Plant inspection

Expert training guide, regular return visit

Sign the contract

Select the model and submit the purchase intention

Get the minimum offer free of charge , please fill in the following information to tell us ( confidential information , not open to the public )

If you are interest in our products or need to know more, please click the consultation button on the right

Get quotation

Get quotation +8613203835178

+8613203835178