Product

Full granulation function and high production efficiency

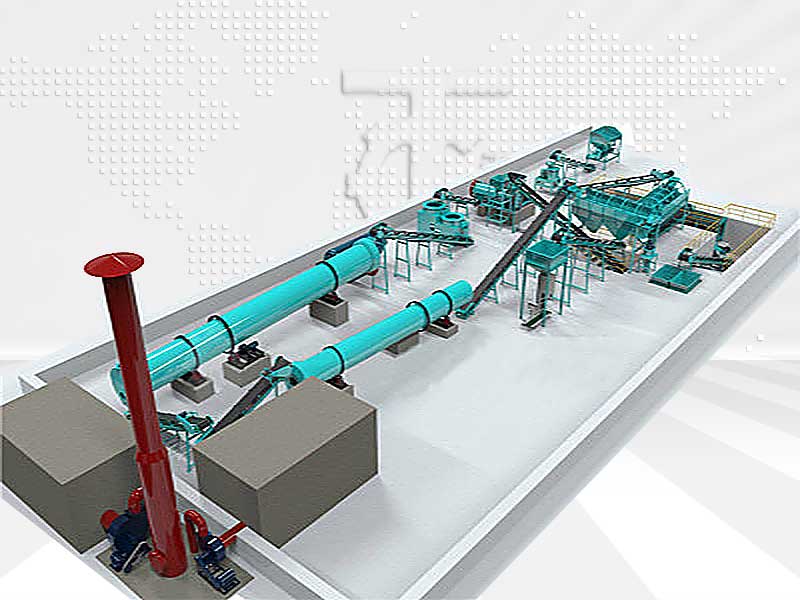

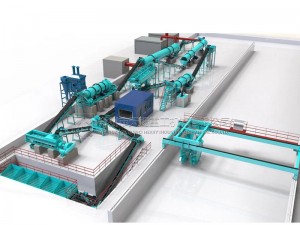

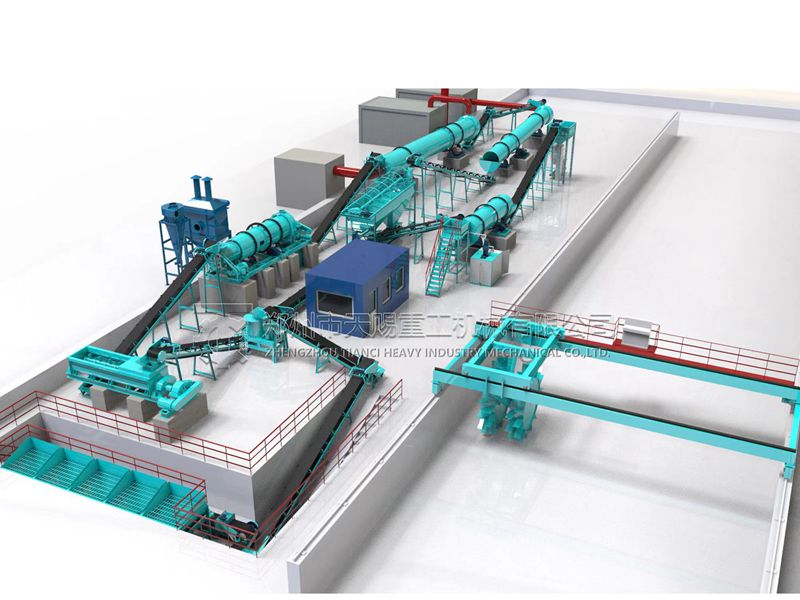

Organic Compound Fertilizer Production Line

Product Despriction

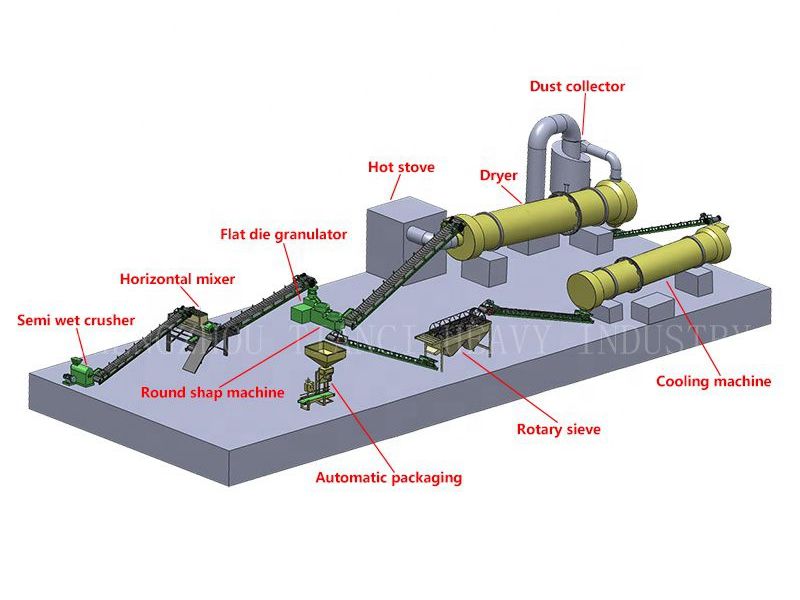

Wet stirring tooth granulator uses high speed rotary mechanical mixing force and the resulting aerodynamic force, so that the fine powder material in the machine to achieve continuous mixing, granulation, spheroidization, densification and other processes, so as to achieve the purpose of granulation.The combination of these two granulation methods makes the granules with higher pellet formation rate.

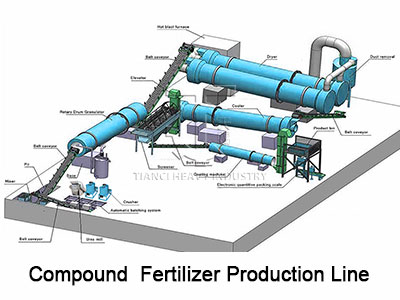

Working Process

Equipments of organic compound fertilizer granules:

| 1 | Fermentation machine | Mainly used for the fermentation of raw materials, to achieve industrial production, no dead ends. |

| 2 | Wet material crusher | Mainly used for the crushing of raw materials to meet the requirements of granulation. |

| 3 | Mixing machine | It is used for mixing and stirring materials, adjusting the moisture content of materials, adding trace elements to meet the needs of granulation. |

| 4 | Granulating machine | for making the fertilizer granules. |

| 5 | Drying machine | It is mainly used for drying after granulation, so that the granules can quickly reduce the moisture at high temperature, which is convenient for storage. |

| 6 | Cooling machine | It is mainly used to cool down and remove moisture after drying, so that the material can quickly reach normal temperature, meet the storage requirements. |

| 7 | Screening machine | It is mainly used for the separation of finished products and returned materials. |

| 8 | Packaging machine | Packing fertilizer granules into bags, which can improve work efficiency and reduce operating costs. |

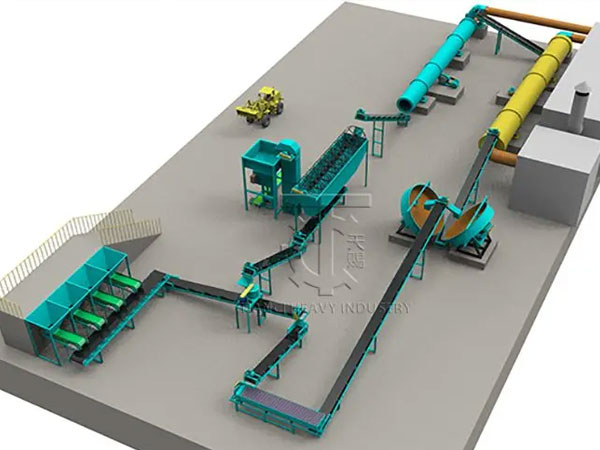

Working Project

Organic compound fertilizer production line from our old customers.

Delivery

Package : wooden package or full 20GP/40HQ container

Request a Quote

Select model and place orders

Select the model and submit the purchase intention

Get the base price

Manufacturers take the initiative to contact and inform the lo

Plant inspection

Expert training guide, regular return visit

Sign the contract

Select the model and submit the purchase intention

Get the minimum offer free of charge , please fill in the following information to tell us ( confidential information , not open to the public )

If you are interest in our products or need to know more, please click the consultation button on the right

Get quotation

Get quotation +8613203835178

+8613203835178