Product

Full granulation function and high production efficiency

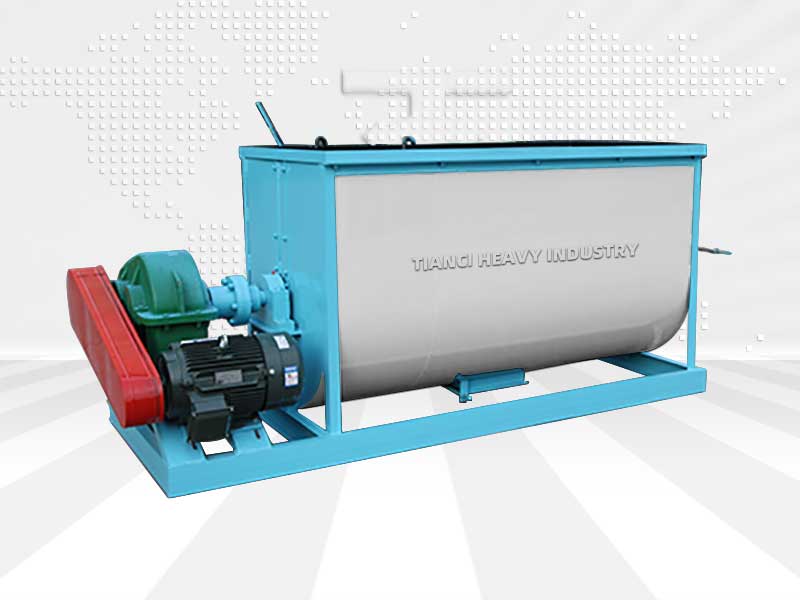

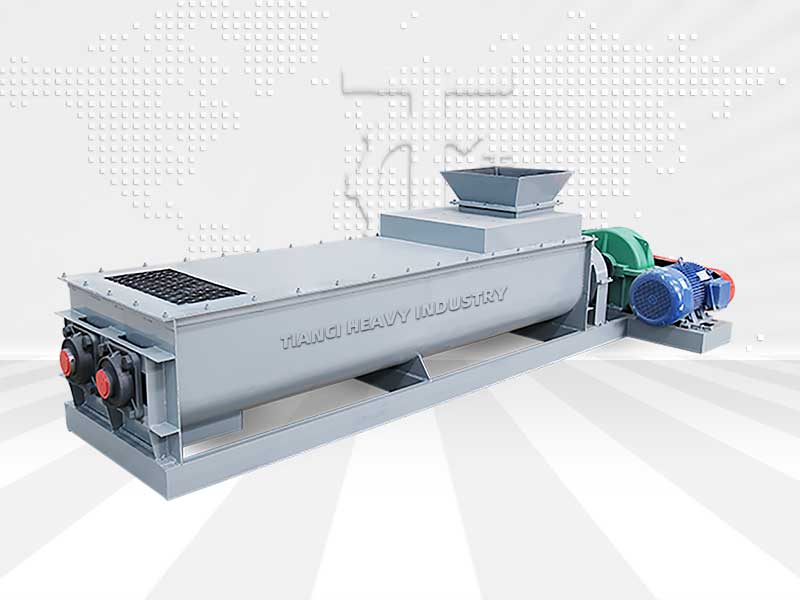

Bulk Blending Fertilizer Mixer Machine

Product Description

Bulk blending fertilizer mixer adopts the operation method of feeding in positive rotation and discharging in reverse rotation, and the material is mixed and exported through special internal spiral mechanism and unique three-dimensional structure.

The equipment has novel design and strong practicability; its feeding system does not store the material, and the mixing system is with high performance; electronic controlling system, with manual, automatic and compound settings, has the characteristics that the similar products do not have.It has the characteristics of high precision, high speed, long life,etc.

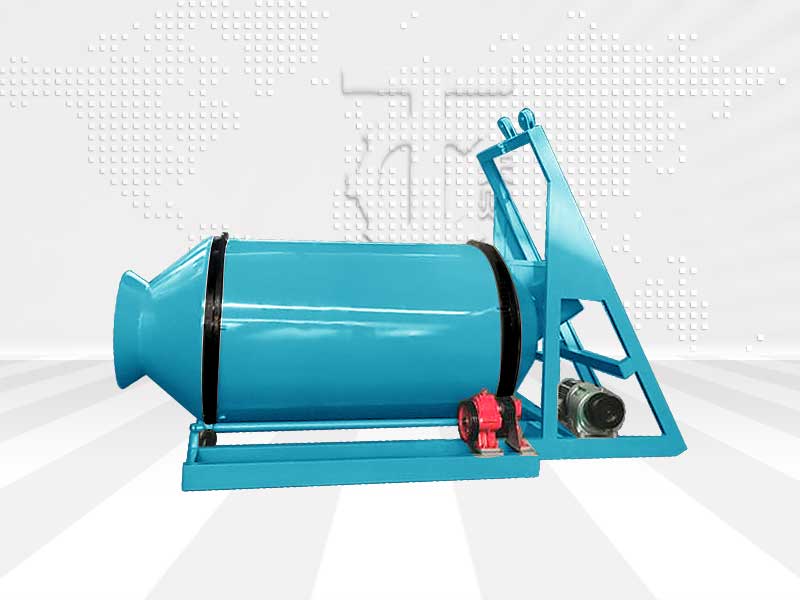

Finished Granules

Blending fertilizer, also known as BB fertilizer or dry mixed fertilizer, is a chemical fertilizer containing any two or three of the three nutrient elements of nitrogen, phosphorus, and potassium. It is made from unit fertilizer or composite fertilizer through simple mechanical mixing, and there is no significant chemical reaction during the mixing process.

Product parameters

| Model | Capacity

(t/h) |

Powder

(kw) |

Mixed Amount

(kg/h) |

| ZYC-1250 | 3-5 | 7.5+4 | 500kg |

| ZYC-1500 | 4-6 | 7.5+4 | 750kg |

| ZYC-2000 | 6-8 | 11+4 | 1000kg |

Directly produced by own factory, with strict quality control

Working Project

Blending fertilizer production line from our old customers:

Delivery

Package : wooden package or full 20GP/40HQ container

Request a Quote

Select model and place orders

Select the model and submit the purchase intention

Get the base price

Manufacturers take the initiative to contact and inform the lo

Plant inspection

Expert training guide, regular return visit

Sign the contract

Select the model and submit the purchase intention

Get the minimum offer free of charge , please fill in the following information to tell us ( confidential information , not open to the public )

If you are interest in our products or need to know more, please click the consultation button on the right

Get quotation

Get quotation +8618937171932

+8618937171932