Product

Full granulation function and high production efficiency

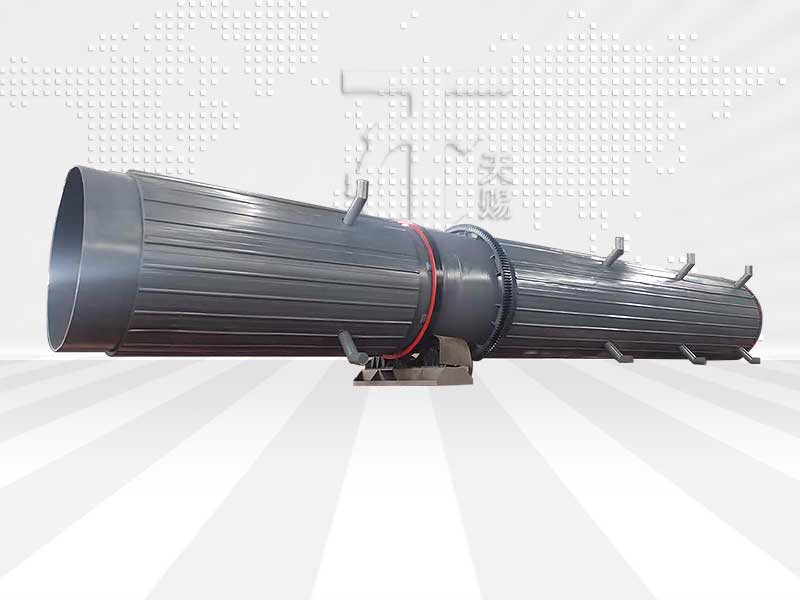

Fertilizer Rotary Drying Machine

Product Introduction

The drum dryer is mainly used for the production of organic fertilizers, composite fertilizers, the drying temperature and particle size of fertilizers, and the drying of other materials. The distribution and angle design of the aircraft lift plate is reasonable, with reliable performance, high heat utilization rate, uniform drying, a small amount of cleaning materials, and convenient maintenance.

Advantages:

1. Small investment, quick results, good economic benefits and reliable performance;

2. Small power, stable operation and convenient maintenance;

3. The process layout is reasonable, and the production cost is low.

Product Parameters

| Model | Diameter (mm) | Length (mm) | Dip Angle (°) | Speed (r/min) | Throughput (t/h) | power (kw) |

| ZG12×6 | 1200 | 6000 | 3 | 5 | 0.5-1 | 5.5 |

| ZG14×7 | 1400 | 7000 | 3 | 5 | 2-3 | 7.5 |

| ZG16×8 | 1600 | 8000 | 3 | 5 | 3-5 | 11 |

| ZG18×9 | 1800 | 9000 | 3 | 4 | 4-6 | 15 |

| ZG20×10 | 2000 | 10000 | 3 | 4 | 6-8 | 18.5 |

Working Principle

Rotary drum fertilizer dryer is mainly used for drying granular organic fertilizer and granular compound fertilizer. The fertilizer particles are transported to the feed port of the fertilizer dryer through the conveyor. The fertilizer particles enter from the feed port of the dryer, and the drying heat source is introduced into the heat source through the induced draft fan from the lower port. Thus, the material falls from the feed port and flows from the bottom to the top with the hot air to form the reverse contact between the fertilizer and the heat source, and then moves to the discharge port of the dryer at different speeds. Under the action of the lifting plate, the fertilizer particles keep lifting and then fall, so that the fertilizer and the heat source are fully contacted, Realize rapid evaporation of water to meet the requirements of target water content.

Working Project

Delivery

Package : wooden package or full 20GP/40HQ container

Long frame will be divided into several parts

Request a Quote

Select model and place orders

Select the model and submit the purchase intention

Get the base price

Manufacturers take the initiative to contact and inform the lo

Plant inspection

Expert training guide, regular return visit

Sign the contract

Select the model and submit the purchase intention

Get the minimum offer free of charge , please fill in the following information to tell us ( confidential information , not open to the public )

If you are interest in our products or need to know more, please click the consultation button on the right

Get quotation

Get quotation +8618937171932

+8618937171932