Product

Full granulation function and high production efficiency

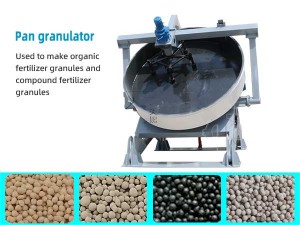

Fertilizer Disc Granulating Machine

Product Description

This series of disc granulator is a new type of inclined disc granulator, suitable for processing powdery materials into ball type granules, widely used in organic fertilizer plants, compound fertilizer plants, sludge waste treatment plants and mines, chemical industry, feed and other industries.

Applications and Features

1. High ball forming rate,the forming rate can reach more than 93%.

2. Long service life of equipment. The reducer and motor are driven by flexible belts, which can start smoothly, reduce the impact force, and improve the service life of the equipment.

3. Rugged and durable, stable operation. The bottom of the granulator board is reinforced by multiple heat-dissipating steel plates, never deformed, thickened and heavy, with a solid base design and no need for anchor bolts.

4. The service life is doubled. The granulation surface plate is lined with high-strength glass fiber reinforced plastic, which is anti-corrosion and durable.

Main Technical Parameters

|

Model |

Inner diameter (mm) |

Side height (mm) |

Volume (m³) |

Rotation speed (r/min) |

Motor power(KW) |

Capacity (t/h) |

Reducer model |

|

ZL10 |

1000 |

250 |

0.4 |

24 |

2.2 |

0.3-0.5 |

XW5-59 |

|

ZL15 |

1500 |

300 |

1.1 |

22 |

5.5 |

0.5-0.8 |

ZQ250-48 |

|

ZL18 |

1800 |

300 |

1.4 |

18 |

5.5 |

0.6-1.0 |

ZQ250-48 |

|

ZL20 |

2000 |

350 |

1.8 |

18 |

7.5 |

0.8-1.2 |

ZQ250-48 |

|

ZL25 |

2500 |

350 |

2.5 |

18 |

7.5 |

1.0-1.5 |

ZQ400-23 |

|

ZL28 |

2800 |

400 |

3.3 |

18 |

11 |

1.0-2.5 |

ZQ400-48 |

|

ZL30 |

3000 |

450 |

3.9 |

16 |

11 |

2.0-3.0 |

ZQ350-23 |

|

ZL32 |

3200 |

500 |

4.3 |

13.6 |

15 |

2.0-3.5 |

ZQ350-23 |

|

ZL36 |

3600 |

550 |

5.5 |

11.3 |

18.5 |

3.0-5.0 |

ZQ400-23 |

|

ZL45 |

4500 |

600 |

6.5 |

8 |

22 |

4.0-6.0 |

ZQ250-48 |

Working Video

Working Project

Delivery

Package : wooden package or full 20GP/40HQ container

Request a Quote

Select model and place orders

Select the model and submit the purchase intention

Get the base price

Manufacturers take the initiative to contact and inform the lo

Plant inspection

Expert training guide, regular return visit

Sign the contract

Select the model and submit the purchase intention

Get the minimum offer free of charge , please fill in the following information to tell us ( confidential information , not open to the public )

If you are interest in our products or need to know more, please click the consultation button on the right

Get quotation

Get quotation +8618937171932

+8618937171932