Product

Full granulation function and high production efficiency

Fertilizer Roller Press Granulator

Product Description

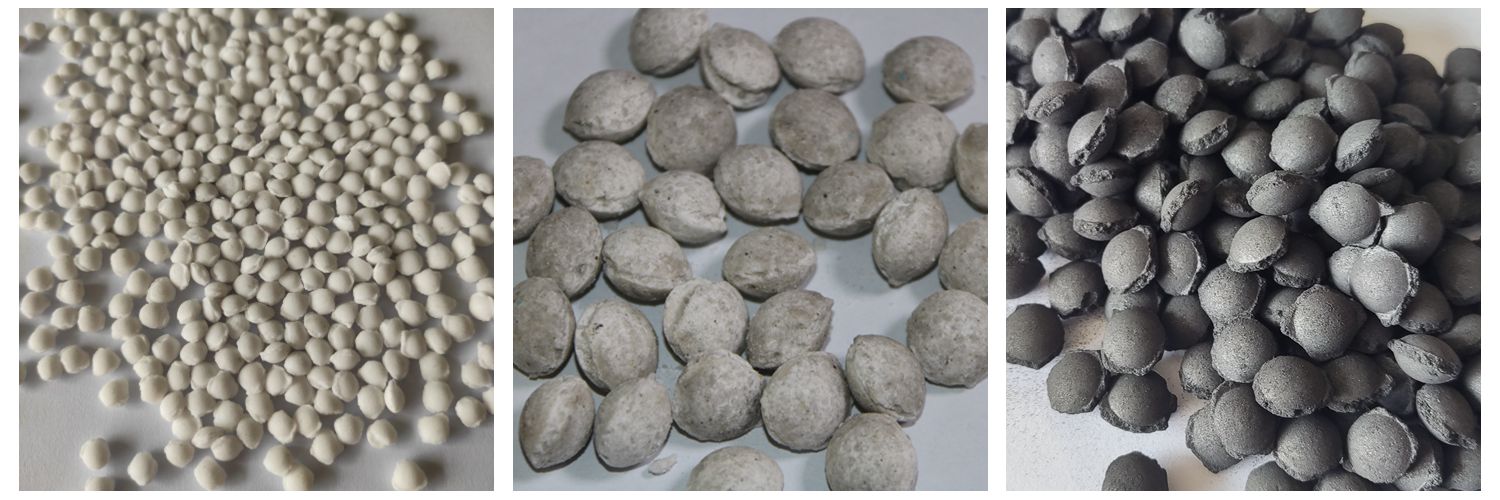

Roller press granulator is produced by non-drying process, granulating at room temperature, and forming at one time. It has the characteristics of less investment, quick effect and good economic benefits. The structure of this machine adopts granulation, forming and screening as a whole, which makes it have the characteristics of beautiful appearance, simple operation and low energy consumption.

The machine has wide adaptability to raw materials, it can not only be used for granulation in fertilizer, feed and chemical industries, but also has good applicability especially for rare earth, metallurgy, coal, biological preparations, and environmental protection projects.

Performance Characteristics

1.The kinetic energy transfer is increased to five slots triangle belt, which fully transfers the motor power and reduces the kinetic energy loss.

2.The reducer adopts the independent research and development design of our company, with high transmission efficiency and stable kinetic energy.

3.Design the feeding and stirring mechanism to ensure that the material can enter the roller die evenly and prevent the feeding mouth from blocking.

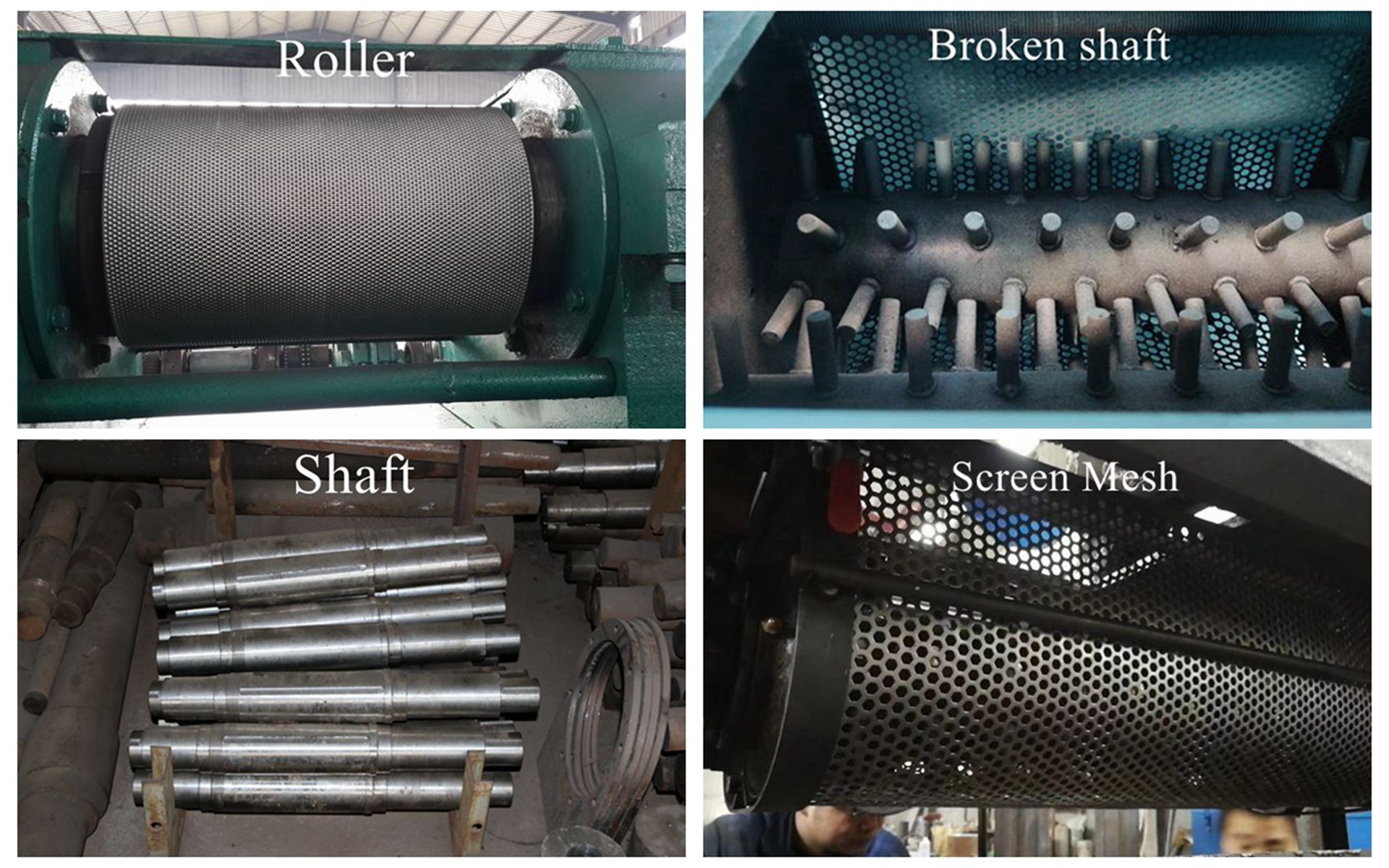

4.Both sides of the lower end of the roller skin mold are equipped with automatic cleaning scraper to prevent materials from sticking to the roller skin.

Working Principle

This series of roller granulation belongs to extrusion sliding model, whose working principle is: the belt and belt pulley are driven by an electric motor, and transmitted to the drive shaft by reducer, and work in the same direction through the open gear and the passive shaft.The material is added from the feed hopper, extruded by the roller, demoded and pelleted, and passed through a pair of chains to the crushing screen studio, where the finished product pellets (balls) are screened and separated, and then the material is returned and mixed with new materials for granulation.With the continuous rotation of the motor and the continuous entry of materials, mass production can be realized.

Main Technical Parameters

|

Model |

DZJ-Ⅰ-1.0 |

DZJ-Ⅰ-2.0 |

DZJ-Ⅰ-3.0 |

DZJ-Ⅰ-4.0 |

DZJ-II-1.0 |

DZJ-II-2.0 |

DZJ-II-3.0 |

|

Production capacity (t/h) |

1-1.5 |

1.5-2.5 |

2.5-3.5 |

3.5-4.5 |

1-2 |

1.5-2.5 |

2.5-3.5 |

|

Power |

15kw |

18.5kw |

22kw |

45kw |

15kw |

18.5kw |

22kw |

|

Pressure roller size |

Φ150×220 |

Φ150×300 |

Φ186×300 |

Φ300×300 |

Φ150×220 |

Φ150×300 |

Φ186×300 |

|

Feeding size |

≤0.5mm |

≤0.5mm |

≤0.5mm |

≤0.5mm |

≤0.5mm |

≤0.5mm |

≤0.5mm |

|

Finished product specifications |

Φ2.5-φ10 |

Φ2.5-φ10 |

Φ2.5-φ20 |

Φ2.5-φ30 |

Φ2.5-φ10 |

Φ2.5-φ20 |

Φ2.5-φ20 |

|

Reducer type |

ZQH350 |

ZQH400 |

ZQH400 |

ZQH500 |

special-purpose |

special-purpose |

special-purpose |

Working Video

Working Project

1-20tph fertilizer plant with roller press granulator:

Delivery

Package : wooden package or full 20GP/40HQ container

Request a Quote

Select model and place orders

Select the model and submit the purchase intention

Get the base price

Manufacturers take the initiative to contact and inform the lo

Plant inspection

Expert training guide, regular return visit

Sign the contract

Select the model and submit the purchase intention

Get the minimum offer free of charge , please fill in the following information to tell us ( confidential information , not open to the public )

If you are interest in our products or need to know more, please click the consultation button on the right

Get quotation

Get quotation +8618937171932

+8618937171932