Product

Full granulation function and high production efficiency

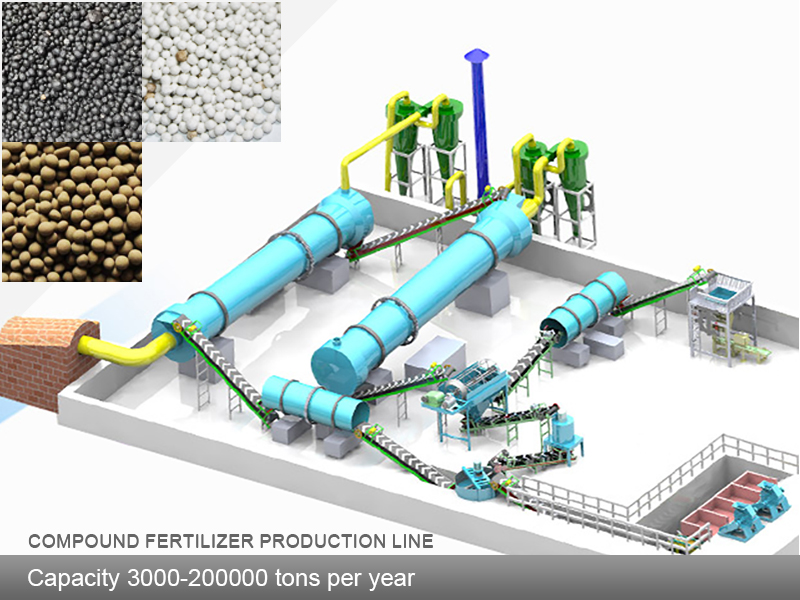

Drum Granulator Fertilizer Production Line

Product Introduce

The compound fertilizer production line uses the drum granulator as the granulation host, and the main process includes the following stages: ① Batching of raw material,②Mixing of raw material, ③ Granulation, ④ Drying of compound fertilizer granules, ⑤ Cooling of compound fertilizer granules, ⑥ Grading and screening of granules, ⑦ Coating of finished granules, ⑧ Packaging.

Main Equipments Of Fertilizer Drum Granulator line

|

No. |

Processes |

Machines |

Function of machines |

|

1 |

Ingredients stage |

Automatic batching machine |

Ratio raw materials by formula |

|

2 |

Raw material crushing |

Chain Crusher |

Grind granules to powder |

|

3 |

Mixing process |

Disc type Mixer |

Mix powder evenly, If necessary, add water, or other micro-elements |

|

4 |

Granulating process |

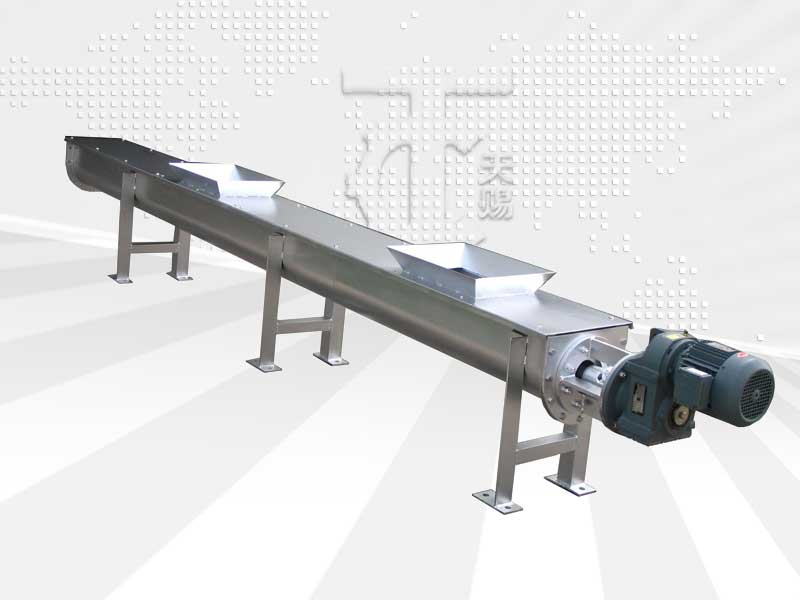

Feeding machine |

Feed mixed powder into granulator evenly |

|

Rotary Drum Granulator |

Make mixed powder into fertilizer granules |

||

|

5 |

Drying process |

Rotary Dryer Drum Fertilizer Cooler |

The heat source adopts gas, heavy oil, biomass fuel, coal Matching needs dust removal system |

|

6 |

Screening process |

Rotary screener machine |

Screen out required size from fertilizer granules |

|

7 |

Coating process |

Coating machine |

Coat color, anti-blocking agent, microelements etc on fertilizer granules |

|

8 |

Packaging process |

Air compressor |

Generate power to packaging machine |

|

Granules Packing Machine |

Package fertilizer granules into bags |

Advantages

Request a Quote

Select model and place orders

Select the model and submit the purchase intention

Get the base price

Manufacturers take the initiative to contact and inform the lo

Plant inspection

Expert training guide, regular return visit

Sign the contract

Select the model and submit the purchase intention

Get the minimum offer free of charge , please fill in the following information to tell us ( confidential information , not open to the public )

Project Case

Learn More Join Us

Standardized cemented carbide products have large inventory, customized products can be newly produced and molds are complete.

Get quotation

Get quotation +8613203835178

+8613203835178